Ultra Motion has over twenty years of heritage working with aerospace leaders to design state of the art linear actuators for both crewed and uncrewed flight applications.

Overview

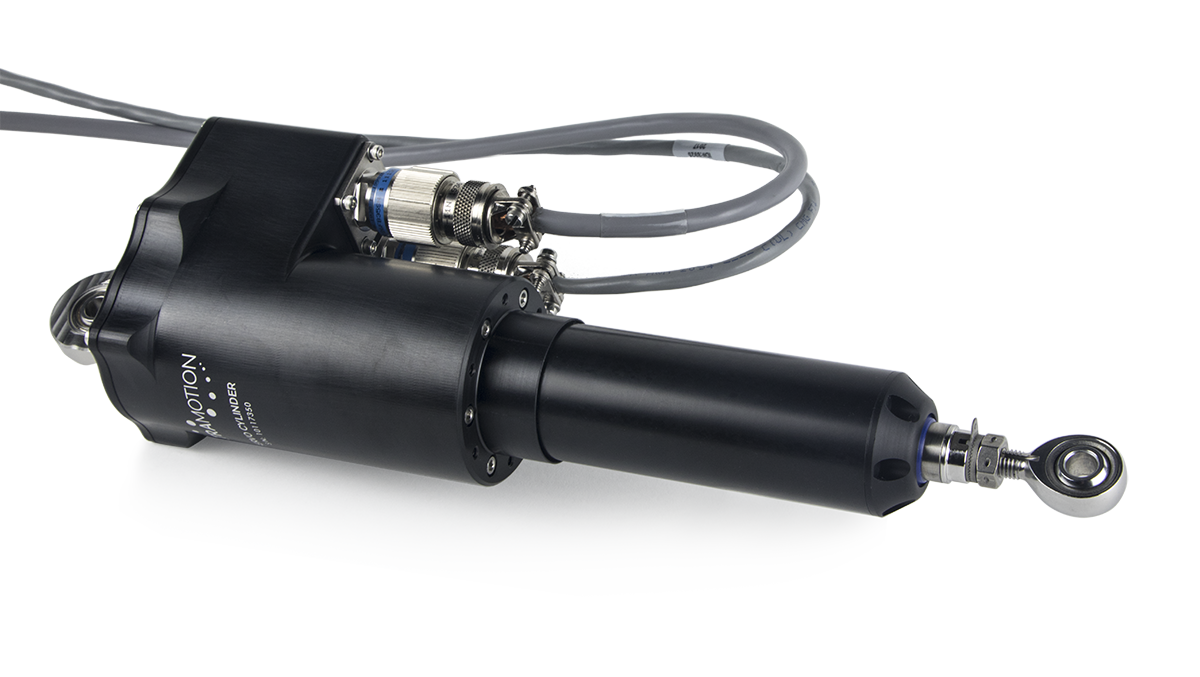

Ultra Motion actuators excel in vehicle control applications, thanks to their remarkably dynamic response capability, environmental dependability, and the seamless integration of BLDC control electronics and absolute position feedback. Made in the USA, Ultra Motion actuators adhere to high-quality standards and are produced in quantities to accommodate the needs of drone swarms and fleets.

Our CAN 2.0B protocol is compatible with the majority of commercially available autopilots and very easy to integrate with custom flight computers.

The CAN 2.0B protocol provides comprehensive telemetry from the actuators including position feedback, phase current, bus voltage, temperature, humidity, and health information. We also support serial communication, RC PWM, 4-20 mA in/out, and other modes.

For enhanced reliability, we offer versions of the Servo Cylinder control board with redundant communication, featuring a primary CAN interface and a backup RS-422/RS-485 serial interface. New dual-redundant actuators and smaller linear servo actuators are soon to be released.

Aerial

Uncrewed Aerial Vehicles

The AM Servo Cylinder has been successfully integrated into many UAV control applications like aileron/rudder/elevator/trim/landing-gear on group 3/4/5 fixed-wing UAVs, thrust vector control of small rocket engines, fin control, and swashplate/tail-rotor control of rotorcraft. Our linear solutions, compared to rotary actuators, are characterized by extremely low or zero backlash, increased stiffness, structural resilience under high shock loads, and rapid dynamic response. These advantages culminate in superior vehicle control and reliability.

Ultra Motion has designed a robust and high-performance rotary actuator for applications that require a rotary solution due to packaging constraints or backwards compatibility with existing solutions. The T3 Series Rotary Servo’s design focuses on dynamic operation in the most demanding environments.

Ultra Motion’s Role in the Phenix UAS Rotorcraft

Images: Phenix Solutions Inc

Surface

Uncrewed Surface Vehicles

The adoption of USVs for commercial and defense applications is growing at a rapid rate and the demands of the marine environment require specially designed actuators. Ultra Motion has 30 years of subsea heritage that has been leveraged to exceed these demands, ensuring reliable actuation throughout constant salt water exposure, shocks from wave slaps, shallow submergence, and temperature extremes. Our actuators have been used for rudder and jet-nozzle control, diverters, mast and accessory deployments, and hydrofoils.

Underwater

Uncrewed Underwater Vehicles

With three decades in the subsea domain, our products have been used in numerous UUV/ROVs, granting us insights into the design requirements for long-term success. All of our subsea products are oil-filled with built-in pressure compensation and make use of specific materials and processes to ensure long term corrosion resistance.

We offer solutions for submergence to 6000+ meters with control electronics built-in, and also without control electronics. Our actuators have been used for subsea vehicle control surfaces, dive-planes, masts, float releases, and accessory deployment applications.

Ground

Uncrewed Ground Vehicles

Designed with resilience in mind, our actuators are fortified against shocks, vibrations, debris, liquid ingress, and extreme temperatures. These attributes are pivotal for ensuring uninterrupted operation in vehicle applications. They have found extensive use in tasks like throttle and transmission control for UGVs, as well as in the direct actuation of brake master cylinders.

Images: Indy Autonomous Challenge

Space

Ultra Motion actuators have a long-standing history in critical space missions, including:

- Serving as a flight-critical component in the launch escape system of a crewed spacecraft.

- Providing thrust vector control for orbital transfer vehicles, upper-stage rockets, and lunar lander engines.

- Powering experimental apparatus aboard the International Space Station.

Our AM and L-Series servos can be vacuum-modified, offering reliable, commercial off-the-shelf solutions tailored to meet the rigorous demands of the rapidly growing new-space industry. These cost-effective, space-ready components help reduce the expense of in-space missions without compromising performance or reliability.

The R-Series is available for applications demanding the highest power density, and we can provide fully custom actuator designs to meet specific requirements.

Image Courtesy LIA Aerospace

Design features including:

- Hardcoat anodized aluminum exteriors with chem-filmed conductive surfaces per MIL-DTL-5541F Type II, Class 3

- 316SS hardware

- 8 to 36 VDC operating voltage range (compliant to MIL-STD-704F for 28 VDC buses)

- -40°C to +80°C minimum temperature range

- Electrically conductive enclosures for EMI/EMC compliance

- Potted internal components for shock and vibration resistance

- Custom molded internal desiccant for long term humidity control

- Pressure balanced oil-filled assemblies with wet-mate connectors for subsea applications to 6000+ meters below seawater.

- Sacrificial anodes for subsea applications